2024 Garden Lighthouse Buyers Guide

Our 2024 Garden Lighthouse Buyers Guide is your go to source for everything garden lighthouses. We believe the best decisions are informed decisions, so let us get started by answering a number of FAQ's on the subject.

What Does Amish Handcrafted Mean?

What does "Amish Crafted", "Amish Handcrafted", or "Amish Made" really mean? These terms are used to identify products that have been made by Amish craftsmen. In many cases they are produced in a shop right at their residence. The general perception about these products is that they are of superior quality and in almost all instances this is the case.

One reason for that perception is Amish craftsmen pass their knowledge and trade skills from one generation to the next, leaving their craftsmen better equipped to produce a quality product. High grade materials, exceptional work ethic, innovative techniques, and integrity also tend to be synonymous with Amish crafted products. As a rule Amish made products are far superior to imports that are bought in the store.

Are Garden Lighthouses Functional?

Yes, Amish garden lighthouses are available in a number of incandescent and LED lighting options.

Standard Electric Lighting: This is generally the default lighting option and includes a standard socket 25-watt bulb. This option is great for creating a soft ambience by the doorway or when your lighthouse doubles as a lamp post.

Standard Electric Lighting with Dusk to Dawn Sensor: At 25 watts this option is perfect for illuminating a garden path or walkway, the sensor automatically turns your light on at dusk and off in the morning, eliminating the need for a switched receptacle.

Electric Revolving Light: Available in incandescent & LED. Looks great by the pond, on the dock, or anywhere you want to replicate an authentic lighthouse. The 360 degree revolving light operates off a small motor and system of polished aluminum reflectors to give it a beacon effect. Comes with 4 watt bulb, 120 volt, 36 RPM.

Electric Revolving Light with Dusk to Dawn Sensor: Available in incandescent & LED, the sensor eliminates the need for a switched receptacle. Looks great by the pond, on the dock, or anywhere you want to replicate an authentic lighthouse. The 360 degree revolving light operates off a small motor and system of polished aluminum reflectors to give it a beacon effect. Comes with 4 watt bulb, 120 volt, 36 RPM.

X-Large Electrical Revolving Light: Large Strobe Electric Revolving Light Kit fits 8' & 12' lighthouses; this light is NOT designed for 6’ or smaller models. This light will most accurately simulate the effect of a real lighthouse with its continuous beam of light revolving 360 degrees. The revolving light is a powerful halogen light in a tough ABS base. It features nylon gears, a durable motor and a stainless steel clamp ring. Great attention-getting characteristics with this 35 Watt Halogen bulb and mirrored revolving backer. Measures Approx. 8" Diameter x 8.5" H, 120 Volt, 0.2 Amperes, 110000 Candelas/Second, 35 Watt Halogen Bulb, 12 RPM, Clear Dome, Visible For 10-12 miles.

Solar Light: Choose this option for a lawn or garden area that has no power source nearby. LED Bulb = 3 Volt, 0.5 Watt, 360 Lumens, Working Time: 6-8 hours (battery fully charged).

Why Should I Buy A Wood Lighthouse?

Price is probably the biggest factor for choosing to purchase a wooden lighthouse over a poly. For a number of years the price difference between wood and poly was not significant, but recently that has changed, poly lumber continues to rise at a faster rate than traditional wood lumber. Depending upon the size of your lighthouse you may find the price difference between wood and poly is several hundred dollars.

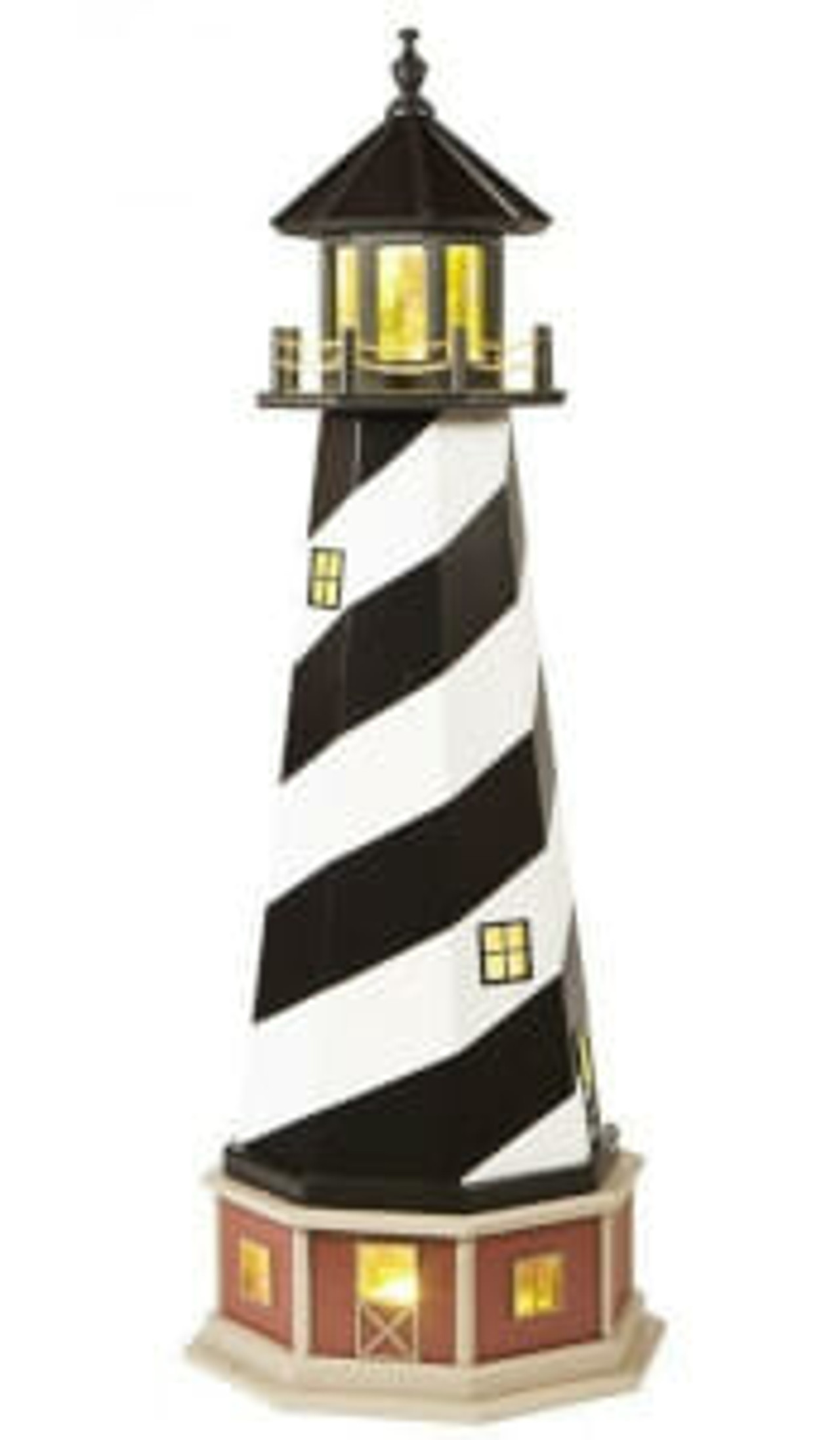

The 2nd argument for a wooden lighthouse is your selection of designs is much larger than with poly. For example, Cape Hatteras is one of America’s most popular lighthouses, its design includes a spiral stripe. The wood lighthouse replica mimics the spiral stripe of the original, this is fairly easy to reproduce by building a wood lighthouse and painting the spiral stripe design onto it.

Poly on the other hand does not respond well to paint, paint does not stick and will crack & peel rather easily. Poly lumber has it’s color added in the manufacturing process, and then designs are created by cutting different colors of poly lumber and fitting them together. This process has its limitations, spiral stripes are not a practical design for poly. Which means your choice of design may determine whether you need to purchase a wood lighthouse over a poly one.

Why Should I Buy A Poly Lighthouse?

Poly is the popular choice for garden lighthouses, outselling wood 3:1, let us consider why:

Poly Does Not Rot Or Decay?

If you are planning to purchase a lighthouse to be placed in a coastal area, we highly recommend choosing poly. Unlike wood, poly is largely unaffected by a high salinity environment.

If you are planning to place a lighthouse on a dock, next to water, or anywhere that the base of the lighthouse will come in contact with water on a consistent basis again you should choose poly over wood, since poly does not rot or decay. If the area you plan to place your lighthouse is consistently damp, again poly will be unaffected by this environment, while wood will rot over time.

Poly Is More Durable Than Wood

Harsh environments have little effect on poly, while bitter cold and scorching sunlight tend to cause wood to split and splinter. Poly is impact-resistant, and is several times stronger than wood.

Poly Is A Maintenance Free Product

If you are looking for a "set it and forget it" piece of nautical decor, then poly is the way to go. Poly lighthouses are constructed from an extremely high performance polymer that doesn’t require sealing, painting or staining. It will not rot or splinter, and contains UV inhibitors that resist fading. It contains no filler, such as wood fiber, that would cause moisture absorption and promote bacterial growth. Marine grade quality stainless steel fasteners are used to assemble poly products, which inhibits rust.

With poly, the UV protect-ant and color are continuously throughout the polymer material, so in the rare occasion that you do scratch the surface, the color is the same under the surface.

Poly Lighthouses Are The Green Choice

Poly is an environmentally friendly product made from recycled materials. While wood lighthouses are often constructed from lumber harvested from sustainable forestry projects, poly lumber is the GREEN choice. Polymer lumber is made by turning existing plastic and resin waste into useful poly lumber for building furniture and other exterior decor products like our lighthouses. More Info.

Poly Care

Lighthouses are often placed in damp or wet locations, this leads to algae and mold issues on wooden lighthouses. With poly the surface is not porous so it naturally resists growth of fungus. If such growth does occur it can be easily washed away, returning the poly to new condition. Scrub gently with mild dish soap and water, then rinse and you are done. (avoid pressure washing).

Why Can't I Get All Lighthouse Designs In Poly?

Poly and wood lumber have their color added with 2 totally different approaches. With wood lumber, paint in the desired colors is applied to the exterior of the lumber. Since the design/pattern is done with paint, it means the design possibilities are almost endless.

Poly lumber has the color added as a dye when the poly lumber is being manufactured. The advantage to this is the color is consistent throughout the material, meaning if you scratch the surface, you have the same color underneath and there is no need to refinish it. Since the color is part of the lumber itself and not added to the surface, design capabilities are limited.

For example, you can’t have the spiral stripe of the Cape Hatteras or the White Shoals lighthouse in a poly garden lighthouse. It would not be possible or cost effective to try and recreate a spiral stripe out of poly. Unfortunately, because poly doesn’t allow paint to adhere to it consistently, design possibilities are somewhat limited.

That being said, there are a number of eye-catching designs available in poly lighthouse models. Recently manufacturers have added “wood grain” textured poly color choices to the color palette. These colors feature a wood grain texture to capture the beauty of wood, while maintaining all the durability advantages of poly lumber.

What Is The Life Expectancy Of A Lighthouse?

The lifespan of a wooden lighthouse is contingent upon the environment in which it is placed and the care it is given. In the optimum environment a wooden lighthouse can be expected to last 7-10 years with some surviving longer. However in the worst environments the life span can be shortened by several years.

Poly lighthouses have a life expectancy of several decades in most environments.

Can I Extend The Life Of A Wood Lighthouse?

Scorching sunlight, bitter cold, and persistent moisture are the worst enemies for a wood lighthouse. Follow these tips to extend its life:

Keep the base of the lighthouse dry, place it on a bed of decorative stone to allow moisture to drain away rather than allowing it to sit on the earth or a bed of mulch.

Consider bringing it in out of the weather for the harsh winter months.

Give your lighthouse a fresh coat of sealer each spring, this will help it resist the elements, and brighten its colors.

Inspect the top for signs of water penetration and decay, at the first sign of moisture getting inside seal the entry hole or purchase a replacement top. Often times it is the top which goes bad first and if replaced early enough you can add a number of years without having to replace the whole lighthouse.

Can I Get Replacement Parts For My Lighthouse?

A variety of replacement parts are available for garden lighthouses, including replacement roofs, tops, bases, lighting, and bulbs.

What Is A Hybrid Lighthouse?

Garden lighthouses are available in a poly material or exterior grade wood. While our Amish craftsmen do everything they can in the manufacturing process, to extend the life of a wood lighthouse, eventually wood will decay and rot. What years of experience have taught us is that the base of the lighthouse where it makes contact with the ground, and the top of the lighthouse are the areas that deteriorate the quickest. A hybrid lighthouse is when we make the top and the base of the lighthouse out of poly to eliminate the deterioration there, but the tower of the lighthouse is still made out of wood to allow for a spiral stripe design. So a hybrid lighthouse is a blend of wood and poly which allows for more flexibility in designs but has a longer life expectancy than a traditional wood lighthouse.

Can Garden Lighthouses Be Used To Cover Wellheads?

Yes, garden lighthouses are hollow and can be slid down over wellheads, and cleanout pipes. Check the product listing, the manufacturer usually provides interior dimensions so you can determine what size lighthouse you need to conceal your wellhead.

Wood Or Poly Which Is The Better Investment?

Wood lighthouses are considerably cheaper than poly but they also have a limited life expectancy, 7-10 years in optimum environments. Poly costs more but in exchange for the price you get a life expectancy upwards of several decades in most environments. As a consumer you need to weigh the maintenance factors and shorter life span of wood against the cost of a virtually maintenance free poly product and make the choice that makes the most sense for you.

Do Lighthouses Ship Assembled?

Garden lighthouses ship with step by step instructions and minimal assembly required. What does that mean?

- Assembly for all 2-3 foot, and 4 foot without base models consists of:

- Removing your lighthouse from the shipping box

- Lay lighthouse on side

- Reach into cavity on bottom of lighthouse a remove lighthouse roof

- Stand lighthouse up

- Remove stretch wrap from lighthouse and roof

- Slide roof down over top of lighthouse and you are done

No tools required, and 2 minutes spent, unpacking & assembling your lighthouse.

For 4 foot with base and larger models the steps are included in the instructions but again assembly is minimal.

- Assembly for 4 foot with base and larger models consists of:

- For Lighthouses With Optional Base

- Remove your lighthouse from the shipping box

- Use a Phillips screw driver to remove protective plywood from bottom. (If shipped with plywood covering cavity)

- Reach into cavity on bottom of lighthouse a remove lighthouse top and roof

- Remove optional base from the shipping box

- Remove stretch wrap from lighthouse base

- With tower standing on its top, position base on it

- Center base on bottom of lighthouse tower, and align corners of base and tower.

- Tighten the 8 predrilled screws with a Philips screw driver.

- Stand lighthouse upright

- Remove stretch wrap from lighthouse and top/roof assembly

- Remove lighthouse roof and set it aside

- Note the 4 screws inside the lighthouse top

- Position your top on the top of the lighthouse tower, center and make sure the corners of the top align with the corners of the tower.

- Tighten the 4 predrilled screws with a Phillips screw driver.

- Slide roof down over top of lighthouse and you are done.

Tools required: 1 Phillips screw driver and 7 minutes spent, unpacking and assembling your lighthouse.

- For Lighthouses Without Optional Base

- Stand lighthouse tower on its top

- Use a Phillips screw driver to remove protective plywood from bottom. (If shipped with plywood covering cavity)

- Reach into cavity on bottom of lighthouse a remove lighthouse top and roof

- Stand lighthouse upright

- Remove stretch wrap from lighthouse and top/roof assembly

- Remove lighthouse roof and set it aside

- Note the 4 screws inside the lighthouse top

- Position your top on the top of the lighthouse tower, center and make sure the corners of the top align with the corners of the tower.

- Tighten the 4 predrilled screws with a Phillips screw driver.

- Slide roof down over top of lighthouse and you are done.

Tools required: Phillips screw driver and 5 minutes spent, unpacking and assembling your lighthouse.